Low MOQ for Electric Wire Crimping Machine - Full Automatic Multi Core Wire Stripping Cutting Machine Max.14mm – Sanao

Low MOQ for Electric Wire Crimping Machine - Full Automatic Multi Core Wire Stripping Cutting Machine Max.14mm – Sanao Detail:

Product Video

Product Introduction

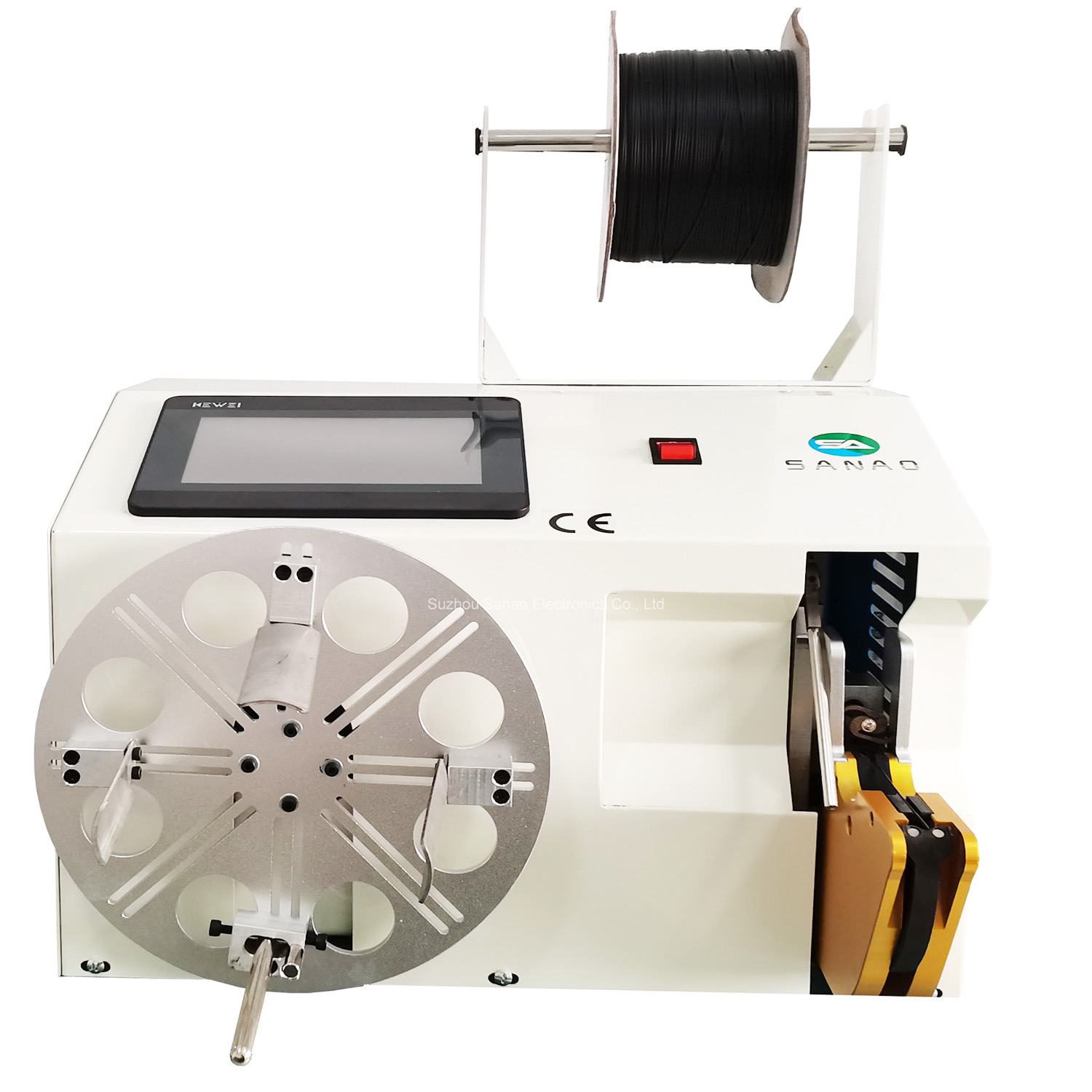

Processing wire range: Max. Process 14MM outer diameter or 7 core sheathed wire, SA-H03 is a economical Automatic sheathe wire strip cut machine, Stripping outer jacket and inner core at one time, It’s adopted 8 wheel belt feeding with English display that it’s more Easier to operate than the keypad model, Machine Widely used in samall sheathed wire and multi core wire, It’s Greatly Improved stripping speed and save labor cost.

Advantage

1. 7 inch touch screen LCD screen display: 7 inch touch screen in Chinese and English, automatic computer program design, simple and clear operations,Our machine have 99 kinds of programs, It can be set according to different stripping requirements, Meet customers’ various stripping requirements.

2. Many kinds of processing methods: Stripping outer jacket or stripping outer jacket and inner core at one time .

3. Motor: Copper core stepper motor with high precision, low noise, precise current which controls motor heating well, longer service life.

4. 16 wheel belt feeding: 16 wheel belting feeing wire that can’t hurt wire, And the belt feeding is more accurate.

5. High quality blade: High-quality raw materials with no burr free incision are durable, wear-resistant and have a longer service life.

Product Parameters

| Model | SA-H03 | SA-H07 |

| Conductor Cross-Section | 4-30mm² | 10-70mm² ; |

| Cutting Length | 1-99999mm | 200-99999mm |

| Cutting Length Tolerances | ≤(0.002*L) mm | ≤(0.002*L) mm |

| Jacket Stripping Length | Head 10-120mm; Tail 10-240mm | Head 30-200mm; Tail 30-150mm |

| Inner Core Stripping Length | Head 1-120mm; Tail 1-240mm | Head 1-30mm; Tail 1-30mm |

| Conduit Diameter | Φ16mm | Φ25mm |

| Production Rate | Single wire :2300pcs/h Sheath wire :800pcs/h (base on wire and cutting length) |

single wire : 2800pcs/h Sheath wire 800pcs/h (base on wire and cutting length) |

| Display Screen | 7 inch touch screen | 7 inch touch screen |

| Drive Method | 16 wheels drive | 32 wheels drive |

| Wire Feed Method | Belt feeding wire, no indentation on cable | Belt feeding wire, no indentation on cable |

Product detail pictures:

Related Product Guide:

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for Low MOQ for Electric Wire Crimping Machine - Full Automatic Multi Core Wire Stripping Cutting Machine Max.14mm – Sanao , The product will supply to all over the world, such as: Iceland , Lithuania , Dominica , Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality items and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.