Advanced Wire Cutting & Stripping Machines for Precision Work

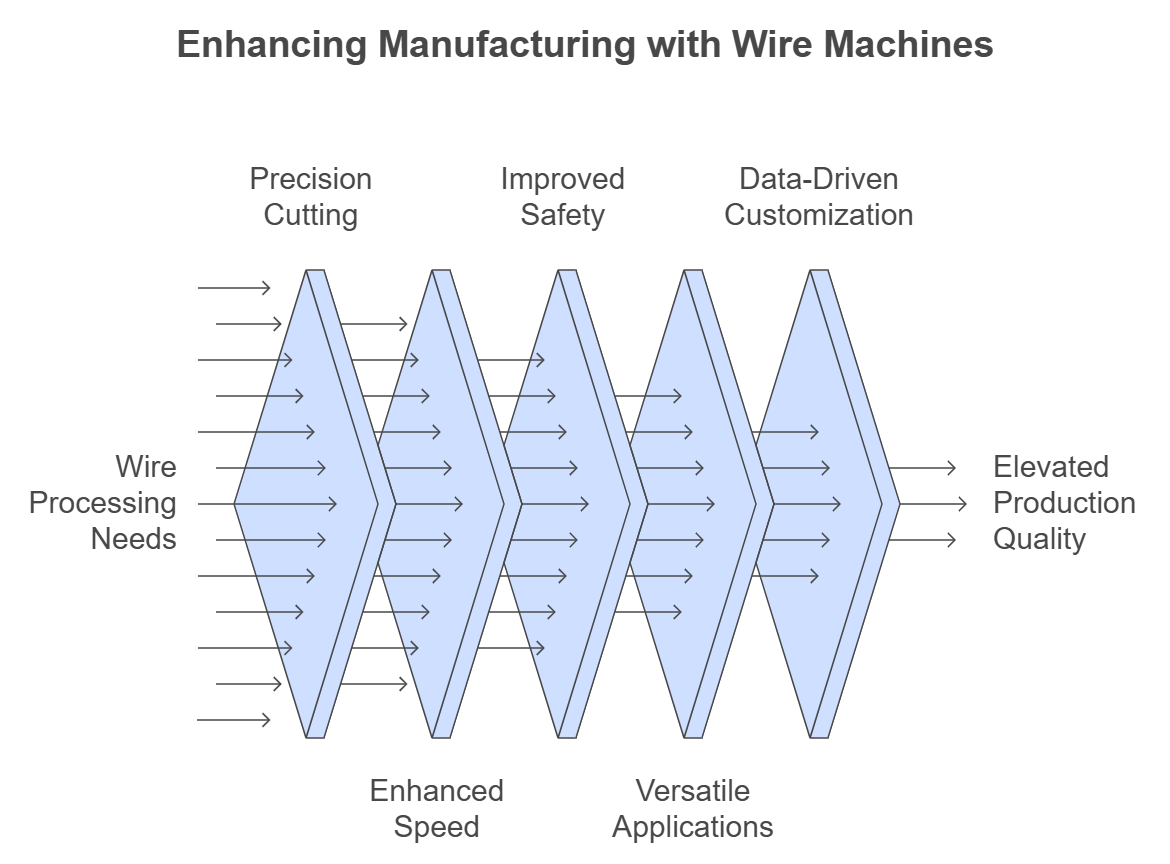

In today’s fast-paced manufacturing environment, precision and efficiency are essential to meet the growing demands of various industries, from automotive to electronics and beyond. At the heart of this efficiency are advanced wire cutting and stripping machines that simplify and refine cable processing. These machines are built to handle even the most intricate tasks, ensuring that manufacturers can produce high-quality results consistently. Here’s a closer look at why investing in a state-of-the-art wire cutting and stripping machine can enhance productivity, ensure accuracy, and boost the overall quality of production.

1. Precision and Consistency for Every Project

For industries that require meticulous detail, precision is non-negotiable. Advanced wire cutting and stripping machines are designed with cutting-edge technology that can accurately measure, cut, and strip wires to exact specifications. This level of precision reduces material waste and enhances consistency across large production batches, meeting the stringent quality standards that industries like aerospace, medical devices, and automotive manufacturing demand. With these machines, you can be confident that every wire processed will meet the same high standard.

2. Enhanced Speed and Efficiency

Time is money in the industrial world. Wire cutting and stripping machines bring exceptional speed to production lines by automating processes that would take much longer to complete manually. With high-speed motors and user-friendly interfaces, these machines can cut and strip multiple wires in seconds, significantly reducing lead times and increasing throughput. By incorporating these machines into your workflow, you can optimize your processes and maximize production efficiency.

3. Improved Safety and Reduced Labor Costs

Manual wire processing can pose safety risks, especially with high voltages and complex wiring. Advanced wire cutting and stripping machines reduce these risks by automating the process, limiting human involvement, and minimizing the potential for errors. The automation these machines provide also means a reduction in labor costs, as fewer workers are needed to handle tedious wire processing tasks. Instead, operators can focus on overseeing operations and managing other critical areas of production.

4. Versatility for Diverse Applications

Modern wire cutting and stripping machines are versatile enough to handle various types of wires, from copper to fiber optics. They come with adjustable settings that can be tailored to different wire diameters, insulation materials, and thicknesses, making them ideal for a wide range of applications. This adaptability ensures that the same machine can be used across multiple projects, providing flexibility and reducing the need for additional equipment investments.

5. Data-Driven Accuracy and Customization

The latest wire cutting and stripping machines often feature digital controls and data integration capabilities, allowing operators to program specific cutting lengths, stripping parameters, and custom specifications. This digital aspect enables precise adjustments for custom projects and the ability to monitor and store performance data, which can be invaluable for quality control and process improvement. By harnessing data-driven insights, manufacturers can optimize settings and improve outcomes on every project.

Elevating Production Quality with Wire Cutting and Stripping Machines

Choosing an advanced wire cutting and stripping machine can transform your manufacturing processes, offering an immediate boost in productivity, consistency, and overall quality. For industries where precision is critical, investing in reliable and high-quality equipment ensures that every project meets rigorous standards. Whether you’re in automotive, telecommunications, or another field requiring accurate wire processing, these machines can help you stay competitive by delivering superior results.

Consider the potential impact of a high-performance wire cutting and stripping machine on your production line. With the right equipment, your team can achieve more efficient workflows, produce top-tier products, and focus on what truly matters—meeting the demands of your clients with precision and excellence.

Post time: Nov-11-2024